Pneumatic Systems Components: Powering the Industrial World with Compressed Air

Pneumatic systems (pneumatic system components) have emerged as a key player in industrial automation, enabling efficient motion and control of various components in automobiles and machinery.

At the core of pneumatic systems lies the utilization of air or gas in a compressed state. These systems operate on the principle of using compressed air to control and power various mechanical processes. While hydraulics employs fluids for similar tasks, pneumatic systems use gas to achieve their objectives.

These pneumatic system solutions from various pneumatic system components supplier, rely on the power of compressed air or gas to perform a wide range of tasks, making them an integral part of modern manufacturing processes.

Let us explore the fascinating world of pneumatic systems components, their functionality, and the advantages they offer over their hydraulic counterparts.

How do Pneumatic Systems components work?

The fundamental components of a pneumatic system provided by a pneumatic system components supplier, include a central compressor and an air tank. The compressor is responsible for compressing the air to a high pressure, and the air is then stored in the air tank until required for use. This compressed air is directed to various components within the system to facilitate their operation.

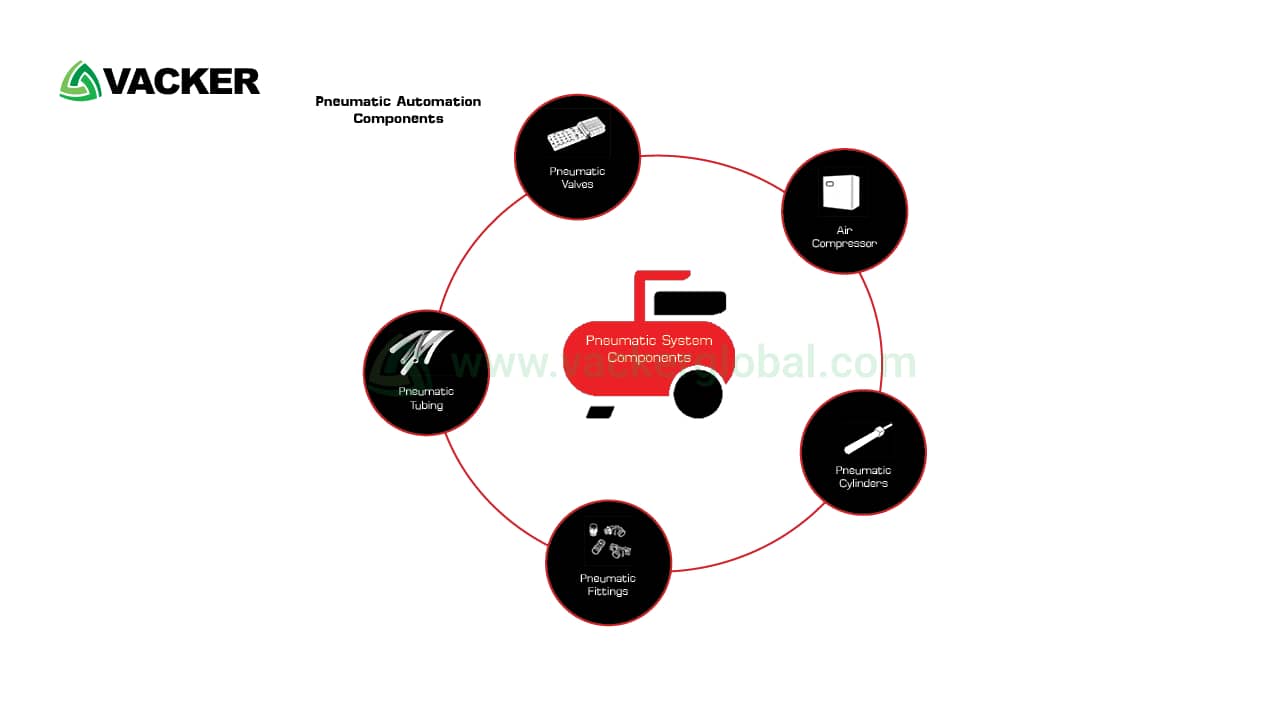

Let’s take a closer look at the key components involved in pneumatic system solutions:

Pneumatic Valves

Pneumatic valves play a crucial role in regulating the flow of compressed air within the system. These valves can be manual or automated and are responsible for controlling the start, stop, and direction of air flow to actuate different processes.

Actuators

Actuators are devices that convert the energy from compressed air into mechanical motion. They are responsible for moving or controlling various components in machinery, such as cylinders, grippers, and rotary actuators.

Solenoid Operated Valves

These are a specific type of pneumatic valve that uses an electromechanical solenoid to control the flow of air. They offer precise and rapid actuation, making them ideal for applications requiring quick responses.

Pneumatic Air Valves

These valves are responsible for controlling the air pressure and flow rate within the system. They ensure the smooth and efficient operation of pneumatic components.

Pneumatic Pipes, Tubing, and Fitting Accessories

To transport the compressed air from the central compressor to various components, pneumatic systems utilize pipes, tubing, and fittings. These components are crucial for maintaining a leak-free and efficient system.

Air Filtration Equipment

Air filtration equipment ensures that the compressed air is clean and free from contaminants, protecting the sensitive pneumatic components from damage and ensuring the longevity of the system.

Advantages of Pneumatic Systems over Hydraulic Systems

Pneumatic system solutions offer several advantages over their hydraulic counterparts, making them a preferred choice in certain applications. Some key advantages include:

Smoother Operations

Pneumatic systems provide smoother and quieter operations compared to hydraulic systems, which can be prone to noise and vibrations due to fluid flow.

Easy Disposal and Refilling

Disposing of air is much simpler and environmentally friendly compared to the disposal of hydraulic fluid. Additionally, refilling the air reservoir is effortless, while hydraulic systems require careful handling of hydraulic fluid and refilling of the reservoir.

Reduced Maintenance

Pneumatic systems generally require less maintenance, as they have fewer components and do not deal with hydraulic fluid-related issues such as leaks and contamination.

Safety and Cleanliness

Compressed air used in pneumatic systems is generally safer to handle than hydraulic fluids, which can be flammable or pose health hazards. Moreover, the absence of fluid leaks ensures a cleaner working environment.

Applications of Pneumatic Systems Components

Pneumatic systems find applications across various industries, owing to their versatility and reliability. Some common applications include:

Manufacturing and Automation

Pneumatic systems are extensively used in manufacturing processes, including assembly lines, material handling, and packaging. Their rapid response times and precise control make them ideal for automating various tasks.

Automotive Industry

Pneumatic systems play a vital role in the automotive industry for tasks such as operating brakes, clutches, and pneumatic suspensions.

Robotics

Pneumatic components are essential for robotic systems, enabling them to perform precise movements and gripping actions.

Aerospace

Pneumatic systems are used in aircraft for functions like landing gear actuation and cabin pressure control.

Medical Equipment

Pneumatic systems find applications in medical devices and equipment, such as ventilators and pneumatic control systems in hospital beds.

Pneumatic systems components have revolutionized the industrial landscape, providing efficient and reliable means of controlling and moving various components. The use of compressed air offers numerous advantages over hydraulic systems, making them a preferred choice in certain applications.

pneumatic system solutions have established themselves as indispensable players across a diverse range of industries, including manufacturing, automation, automotive, and aerospace. Their pivotal role in driving progress and innovation is evident, making them a preferred choice for various applications.

As technology advances, we can anticipate even more exciting developments in pneumatic systems components, further solidifying their position as essential elements within the industrial world.

To explore more about the world of pneumatic systems components and discover top-quality solutions, visit the pneumatic system components supplier Vacker, where expertise meets excellence.

Leave a Reply